February 26, 2021

For investors the situation is much the same: First impressions count!!!! Even though you may not be able to tell a book by its cover, you'll probably pay more for a book if the cover is inviting, and attractive.

If you have a home is for sale or soon to be for sale, in addition to a general cleaning here are some steps Tungsten Carbide Rods you can take to benefit from that all-important first look:

1. Start with the outside. Mow the law, prune bushes, remove dead branches and get rid of outdoor furniture you don't intend to move.

2. Paint the front door and window frames, or at least clean them up.

3. Check for leaks. A drip may not seem important, but does it suggest poor maintenance in those places that maybe the buyer can't see? Eliminate buyer worries and fix the little items which may be seen as clues relating to the general condition and upkeep of the house.

4. Clean out closets and storage areas. Paint them off-white inside to make them seem roomier.

5. Have a professional cleaning company clean the carpets. I would suggest this only if you are not replacing the carpets.

6. Caulk around tubs and sinks. New caulk invariably carbide rods looks better than old caulk, and you'll also prevent leaks.

7. Replace bulbs that don't work and use as much wattage as is appropriate for each fixture, usually I use 100watt bulbs everywhere. Bright lights make homes seem, well.Brighter!

8. If there are outdated tiles in kitchen and bath areas make sure and paint them with an appropriate color?here are some of the colors I would recommend?.high gloss white. It will amaze you the change this simple fix can have on a sixties type of bathroom.

9. Replace some old bathroom fixtures with a bar light above the mirror or medicine cabinet.

10. People have allergies and if there are sign of a pet make sure to get rid of them before showing the home, eg: pet doors.

11. Homes in a given location and price range battle for a common pool of buyers. Make sure that you do the things that will set your house apart from the rest. A key factor in this is offering some assistance with financing whether in a second mortgage or offering your mortgage to be assumed.

Good luck and Happy Investing

Posted by: philiposbo at

06:02 AM

| No Comments

| Add Comment

Post contains 405 words, total size 2 kb.

February 24, 2021

As ridiculous as it may seem, there was a very good reason for doing this.

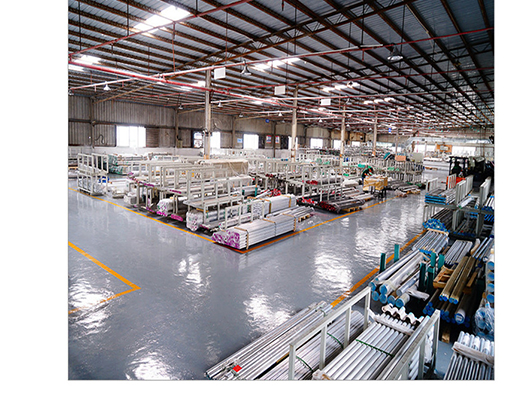

Firstly, this is a high technology manufacturing facility that manufactures products under extremely clean and dust-free conditions. With clean room facilities standard that goes down to class 10, it is very, very clean indeed. As such it is very important that dust do not enter into the clean room under manufacturing conditions. So in the past, all evacuation drills were done just before we had a planned plant shutdown for maintenance.

Secondly, during the past few years, whenever an evacuation drill was organized, the administration offices were usually closed, and all the workers will be making use of the opportunity to take their vacation. Practically nobody will be around. Even the production workers will be taking their vacation when they have stopped all their machines and handed over the plant for shutdown maintenance.

So when the office workers say that they do not know what to do in a fire situation, we can fully understand why. They had not been taking part in any fire evacuation drill before. It is not enough just to describe what will happen in an evacuation to them - somehow, we have Tungsten Weight to organize an actual evacuation drill for the office workers themselves. The challenge is to do it while the manufacturing production is still operating.

Any mistake that will cause people from the manufacturing clean rooms to evacuate will be disastrous to the company. The stakes are high.

The fire protection alarm system in our building is wired in such a way that any triggering of the alarm by activating a break glass, smoke detector, heat detector or sprinkler flow switch will eventually trigger the general alarm for the whole building if it is not acknowledged and reset back within 3 minutes. This is a safety feature to ensure that somebody actually goes and check the situation whenever there is an alarm.

In our fire evacuation plan, all the occupants had been trained to open the doors of the nearest tungsten carbide exit point and escape from the building whenever it is confirmed that a real fire or emergency has occurred. This will ensure that nobody is left inside the building if there is a real emergency.

However, as far as our manufacturing clean room is concerned, this will be disastrous. All the products, rooms, machinery and clean room environment will be destroyed once the doors were opened to the atmosphere. It will take hours to recover back to the original condition. The losses will be enormous.

Although normal communications through supervisors and public address systems can be done, still there is too much at stake to take that risk.

That was our first option. Relying on human communications leaves too much on uncertainty. We have to make it completely idiot-proof. This option is not fool proof. Somebody might claim that they did not get the message.

Our second option was to re-program the fire alarm system to exclude all the areas in the clean rooms. This option was a bit tricky as there were some uncertainty as to how the alarm bells were wired up. We had to admit that although everything was drawn on paper on the as-built drawings, we were not 100% sure whether the re-programming will cover all the alarm bells inside the clean rooms or not. Moreover, there had been some renovation done on the existing building and nobody had taken the trouble to test the alarm bells then. So this option was also shelved.

Our third option was to re-wire the existing bells specifically only for the offices, so that we can trigger only the office areas. This seems a pretty good option, except that the preparation re-wiring work will have to be done at the installation itself. During the re-wiring period, the office itself would not be protected by the fire alarm system. In add

Posted by: philiposbo at

02:08 AM

| No Comments

| Add Comment

Post contains 661 words, total size 4 kb.

February 19, 2021

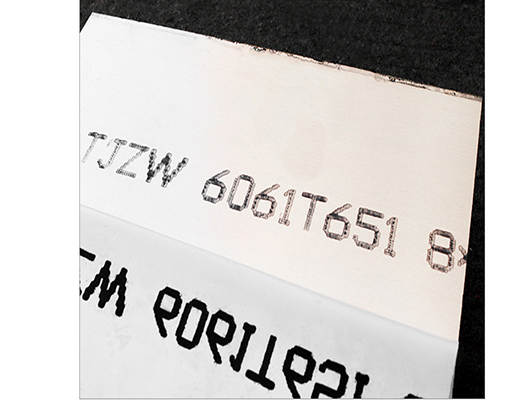

Zhuzhou Jinxin strength manufacturers provide you with the price of Hebei cemented carbide bars-manufacturers, welcome to call.

Hebei cemented carbide bar price-manufacturer, the embryonic body is composed of PCBN composite sheet, which directly combines the CBN layer and the cemented carbide substrate under high temperature and high pressure, and is made into various welded cutting tools or blades through the cutting and welding process.The whole PCBN sintered block is directly sintered without the alloy matrix to become the whole PCBN knife. After sharpening, it is made into a cubic boron nitride polycrystalline blade..Composition equipment The composition equipment used in foreign countries is mostly double-sided topping presses, and most domestically are topping presses..

Product Category Sharp tooth milling cutter grinds a narrow edge zone on the flank face to form a relief angle. Due to the reasonable cutting angle, its life is longer.The tooth back of the sharp tooth milling cutter has three forms: straight curve and broken line.Straight tooth backs are often used for finishing milling cutters with fine teeth.Curved and broken-line tooth backs have better tooth strength and can withstand heavier cutting loads. They are often used for coarse-tooth milling cutters..

Common sense of programming Because the CNC milling machine is configured with different CNC systems, the instructions used have certain differences in definition and functions, but their basic functions and programming methods are stillTungsten Carbide Burr BlankAre the same.The main function of CNC milling machine point control function The point control function of CNC milling machine is mainly used for hole processing of workpieces, such as center drilling, positioning, drilling, reaming, countersinking, reaming, and boring..

Function of subroutine If processing the same or similar part of the workpiece, write it into a subroutine and call it by the main program, thus simplifying the program structure.The function of quoting subroutines makes the machining program modular, which is divided into several modules according to the working procedures of the machining process, which are respectively written into subroutines, which are called by the main program to complete the processing of the workpiece.This modular program is convenient for processing debugging and optimizing processing technology.The tool length compensation function changes the compensation amount of the tool length, which can compensate the length deviation value after the tool change, and can also change the plane position of the cutting process, and control the axial positioning accuracy of the tool.Canned cycle processing function. Application of canned cycle processing instructions can simplify processing procedures and reduce programming workload.

General-purpose cemented carbide adds appropriate amount of rare metal carbides, such as tantalum carbide and niobium carbide, to the above two cemented carbides to refine their grains, improve their room temperature hardness and high temperature hardness, wear resistance, bonding temperature and resistance Oxidation can increase the resistance of the alloy. Therefore, this type of cemented carbide knife has better comprehensive cutting functions and versatility. Its trademarks are YWYW2 and YA6, etc., because of its relatively expensive price, and is mainly used for difficult machining Information, such as high-strength steel, heat-resistant steel, stainless steel, etc..

Under normal circumstances, wet cutting does not significantly improve the

Posted by: philiposbo at

02:23 AM

| No Comments

| Add Comment

Post contains 522 words, total size 4 kb.

February 08, 2021

Gaosheng Aluminum (Dongguan) Co., Ltd. will give you a detailed interpretation of the relevant knowledge and details of Jiangsu aluminum alloy bar manufacturers and alloy aluminum bar manufacturers: In 1915, Alcoa invented the 2017 alloy, and in 1933 invented the 2024 alloy to make aluminum in aircraft Applications in.In 1933, Alcoa invented 61 alloy, and then created the extruder quenching process, which significantly expanded the application range of extruded profiles.In 19, Alcoa invented the electrical aluminum alloy 10 and made it into a steel core aluminum stranded wire, creating a pioneer in high-voltage remote power transmission.

Aluminum pipe, mainly used in the refrigeration system of 10¡æ to -45¡æ cold storage, is the evaporator used in all kinds of food freezing cold storage.The inlet and outlet parts of the aluminum pipe use high-frequency resistance welding copper-aluminum joints, the thickness of the aluminum pipe is 2mm without drop, and the pressure is 5Mpa.Aluminum exhaust refrigeration capacity, K value ¡Ö10W/(m¡æ[average value], according to cold storage design specifications, Q=K¡¤A¡¤¦¤t, temperature difference ¦¤t taken in the actual proportioning process ¦¤t=10¡æ.Iron Fe0.35 chromium Cr0.10 Titanium Ti0.10 manganese Mn0.10 zinc Zn0.10 mg Mg0.45¡«0.9 Copper Cu0.10 silicon Si0.20¡«0.60 Aluminum Al remaining chemical composition editing The molten aluminum after casting is cooled and cast into various specifications of round casting rods through the deep well casting system under certain casting process conditions.

In 1915, Alcoa invented the 2017 alloy and in 1933 invented the 2024 alloy, making aluminum in aircraftTungsten Carbide RodsApplications in.In 1933, Alcoa invented 61 alloy, and then created the extruder quenching process, which significantly expanded the application range of extruded profiles.In 19, Alcoa invented the electrical aluminum alloy 10 and made it into a steel core aluminum stranded wire, creating a pioneer in high-voltage remote power transmission.

In 1915, Alcoa invented the 2017 alloy and in 1933 invented the 2024 alloy, which enabled the rapid expansion of the application of aluminum in aircraft.In 1933, Alcoa invented 61 alloy, and then created the extruder quenching process, which significantly expanded the application range of extruded profiles.In 19, Alcoa invented the electrical aluminum alloy 10 and made it into a steel core aluminum stranded wire, creating a pioneer in high-voltage remote power transmission.

Aluminum pipe, mainly used in the refrigeration system of 10¡æ to -45¡æ cold storage, is the evaporator used in all kinds of food freezing cold storage.The inlet and outlet parts of the aluminum pipe use high-frequency resistance welding copper-aluminum joints, the thickness of the aluminum pipe is 2mm without drop, and the pressure is 5Mpa.Aluminum exhaust refrigeration capacity, K value ¡Ö10W/(m¡æ[average value], according to cold storage design specifications, Q=K¡¤A¡¤¦¤t, temperature difference ¦¤t taken in the actual proportioning process ¦¤t=10¡æ.Iron Fe0.35 chromium Cr0.10 Titanium Ti0.10 manganese Mn0.10 zinc Zn0.10 mg Mg0.45¡«0.9 Copper Cu0.10 silicon Si0.20¡«0.60 Aluminum Al remaining chemical composition editing The molten aluminum after casting is cooled and cast into various specifications of round casting rods through the deep well casting system under certain casting process conditions.

Pay attention to environmental health safety and recycling.Aluminum is a green product, and aluminum should play a greater role in creating a better life.Aluminum processin

Posted by: philiposbo at

03:06 AM

| No Comments

| Add Comment

Post contains 525 words, total size 4 kb.

Gaosheng Aluminum will carefully build Jiangsu aluminum alloy bar manufacturer for you-which one is better, please call!

Jiangsu aluminum alloy bar manufacturer-which one is better, sealing will seal the pores of the porous oxide film formed after anodization, so that the oxide film has enhanced anti-pollution, corrosion resistance and wear resistance.The oxide film is colorless and transparent. Using the strong adsorption of the oxide film before sealing, some metal salts can be adsorbed and deposited in the film holes, which can make the appearance of the profile show many colors other than the natural color (silver white), such as black bronze gold and stainless steel Color.

In 1915, Alcoa invented the 2017 alloy and in 1933 invented the 2024 alloy, which enabled the rapid expansion of the application of aluminum in aircraft.In 1933, Alcoa invented 61 alloy, and then created the extruder quenching process, which significantly expanded the application range of extruded profiles.In 19, Alcoa invented the electrical aluminum alloy 10 and made it into a steel core aluminum stranded wire, creating a pioneer in high-voltage remote power transmission.

In 1915, Alcoa invented the 2017 alloy and in 1933 invented the 2024 alloy, making aluminum in aircraftApplications in.In 1933, Alcoa invented 61 alloy, and then created the extruder quenching process, which significantly expanded the application range of extruded profiles.In 19, Alcoa invented the electrical aluminum alloy 10 and made it into a steel core aluminum stranded wire, creating a pioneer in high-voltage remote power transmission.

The physical enterprise is not closely integrated with the capital market.Rough statistics, there are currently only a few aluminum processing companies in China listed at home and abroad. Compared with the small number of processing industries, the aluminum processing companies have not been able to use the power of the capital market to achieve their own leapfrog development. At the same time, the listed companies It also failed to give full play to the role of the market in boosting the development of the company. This will be the next step for China's aluminum processing industry..

In 1915, Alcoa invented the 2017 alloy and in 1933 invented the 2024 alloy, which enabled the rapid expansion of the application of aluminum in aircraft.In 1933, Alcoa invented 61 alloy, and then created the extruder quenching process, which significantly expanded the application range of extruded profiles.In 19, Alcoa invented the electrical aluminum alloy 10 and made it into a steel core aluminum stranded wire, creating a pioneer in high-voltage remote power transmission.

In 1915, Alcoa invented the 2017 alloy and in 1933 invented the 2024 alloy, which enabled the rapid expansion of the application of aluminum in aircraft.In 1933, Alcoa invented 61 alloy, and then created the extruder quenching process, which significantly expanded the application range of extruded profiles.In 19, Alcoa invented the electrical aluminum alloy 10 and made it into a steel core aluminum stranded wire, creating a pioneer in high-voltage remote power transmission.

For extrusion production, extrusion temperature is a basic and critical process factor.Extrusion temperature has a great impact on product quality, production efficiency, mold life, energy consumption, etc..The important problem of extrusion is the control of the metal temperature. From the heating of the ingot to the quenching of the extruded profile,

Posted by: philiposbo at

03:06 AM

| No Comments

| Add Comment

Post contains 549 words, total size 4 kb.

February 07, 2021

Gaosheng Aluminum carefully builds the price of professional aluminum alloy bars in Inner Mongolia for you-manufacturer, please call!

Inner Mongolia professional aluminum alloy bar price-manufacturer, aluminum curtain wall has a large seasonal temperature difference. In the early spring and late autumn seasons when the temperature is low, the thermal effect of sunlight is very strong, especially the darker aluminum plate is heated more. At different temperatures, inside the curtain wall frame with a larger thermal expansion value per meter, the sun's influence is weak. The aluminum plate and the frame can produce a temperature difference of over 80¡ãC. When the size of the aluminum plate has a larger linear expansion difference.If the curtain wall panel structure adopts hemming, the structure of fixing the aluminum plate on the frame with screws will cause the thermal stress on the surface of the aluminum plate to be unable to release, forcing the plate surface to yield, and outward deformation will occur under the action of air. This deformation phenomenon is quite considerable , Especially when steel profiles are used in the internal curtain wall frame of aluminum panels, since the thermal expansion coefficient of aluminum is generally twice that of steel, the deflection of the same size panel will be twice the value in the table. When some manufacturers fix the panel corners, The screw holes of the fixed plate in the length or width direction of the plate are processed into long holes, but the plate is still deformed after installation, and this connection method cannot meet the requirements of the curtain wall plane deformation.The plate is fixed with the structural analysis frame of the curtain wall, and the thermal stress cannot be released, resulting in changes..

28 aluminum plate.Aerospace vehicle structure and weapon structure 2036 aluminum plate.Automobile body sheet metal parts 2024 aluminum plate.Aircraft structure rivet components truck wheel hub propeller components and other various structural parts 2017 aluminum plate.It is a 2XXX series alloy that has been industrially applied, with a narrow application rangeTungsten Weight, Mainly for rivet general mechanical parts structure and transportation tool structure parts, propellers and accessories.

Grasp the opportunity of "One Belt One Road" and implement the strategy of going global.The "Belt and Road" initiative provides a good opportunity for Chinese aluminum processing companies to "go global". "Going global" can not only extend the industrial chain, but also open up new markets, so as to effectively deal with other trade frictions. We must make good use of " One Belt One Road Initiative.

Disposal of the appearance of aluminum alloy produces waste water, which is mainly acid-base waste water, which contains a small amount of harmful anions and cations such as Ni2+Sn2+F-. The disposal method is acid-base neutralization.The wastewater is usually acidic, so it needs to be neutralized by adding alkali and adjust the PH value to about 7¡«5..At the same time during the neutralization process, the cations Al3+Ni2+Sn2+Cr3+, etc. all form hydroxide precipitates.The waste water from neutralization and precipitation is pumped into the coagulation tank with a pump, and at the same time, the dissolved polyamide flocculant is pumped into the coagulation tank with a quantitative pump, and the waste water enters the sedimentation tank after coagulation. The sedimentation method is inclined plate sediment

Posted by: philiposbo at

02:03 AM

| No Comments

| Add Comment

Post contains 549 words, total size 4 kb.

February 05, 2021

Gaosheng Aluminum will carefully build Jiangsu aluminum alloy bar manufacturer for you-which one is better, please call!

Jiangsu aluminum alloy bar manufacturer-which one is better, sealing will seal the pores of the porous oxide film formed after anodization, so that the oxide film has enhanced anti-pollution, corrosion resistance and wear resistance.The oxide film is colorless and transparent. Using the strong adsorption of the oxide film before sealing, some metal salts can be adsorbed and deposited in the film holes, which can make the appearance of the profile show many colors other than the natural color (silver white), such as black bronze gold and stainless steel Color.

In 1915, Alcoa invented the 2017 alloy and in 1933 invented the 2024 alloy, which enabled the rapid expansion of the application of aluminum in aircraft.In 1933, Alcoa invented 61 alloy, and then created the extruder quenching process, which significantly expanded the application range of extruded profiles.In 19, Alcoa invented the electrical aluminum alloy 10 and made it into a steel core aluminum stranded wire, creating a pioneer in high-voltage remote power transmission.

In 1915, Alcoa invented the 2017 alloy and in 1933 invented the 2024 alloy, making aluminum in aircraftApplications in.In 1933, Alcoa invented 61 alloy, and then created the extruder quenching process, which significantly expanded the application range of extruded profiles.In 19, Alcoa invented the electrical aluminum alloy 10 and made it into a steel core aluminum stranded wire, creating a pioneer in high-voltage remote power transmission.

The physical enterprise is not closely integrated with the capital market.Rough statistics, there are currently only a few aluminum processing companies in China listed at home and abroad. Compared with the small number of processing industries, the aluminum processing companies have not been able to use the power of the capital market to achieve their own leapfrog development. At the same time, the listed companies It also failed to give full play to the role of the market in boosting the development of the company. This will be the next step for China's aluminum processing industry..

In 1915, Alcoa invented the 2017 alloy and in 1933 invented the 2024 alloy, which enabled the rapid expansion of the application of aluminum in aircraft.In 1933, Alcoa invented 61 alloy, and then created the extruder quenching process, which significantly expanded the application range of extruded profiles.In 19, Alcoa invented the electrical aluminum alloy 10 and made it into a steel core aluminum stranded wire, creating a pioneer in high-voltage remote power transmission.

In 1915, Alcoa invented the 2017 alloy and in 1933 invented the 2024 alloy carbide rods, which enabled the rapid expansion of the application of aluminum in aircraft.In 1933, Alcoa invented 61 alloy, and then created the extruder quenching process, which significantly expanded the application range of extruded profiles.In 19, Alcoa invented the electrical aluminum alloy 10 and made it into a steel core aluminum stranded wire, creating a pioneer in high-voltage remote power transmission.

For extrusion production, extrusion temperature is a basic and critical process factor.Extrusion temperature has a great impact on product quality, production efficiency, mold life, energy consumption, etc..The important problem of extrusion is the control of the metal temperature. From the heating of the ingot to the quenching of the extruded profile,

Posted by: philiposbo at

01:17 AM

| No Comments

| Add Comment

Post contains 548 words, total size 4 kb.

February 03, 2021

Gaosheng Aluminum Co., Ltd. carefully builds aluminum alloy rods for you, which one is better-how much, please call!

Which aluminum alloy bar is better-how much is it? Alcoa invented 2017 alloy in 1915 and 2024 alloy in 1933, which enabled the rapid expansion of aluminum applications in aircraft.In 1933, Alcoa invented 61 alloy, and then created the extruder quenching process, which significantly expanded the application range of extruded profiles.In 19, Alcoa invented the electrical aluminum alloy 10 and made it into a steel core aluminum stranded wire, creating a pioneer in high-voltage remote power transmission.

66 aluminum plate.Forging and welding structure extruded material 63 aluminum plate.Building profiles, irrigation pipes, and extruded materials 61 aluminum plates for vehicle benches, furniture, fences, etc.A variety of industrial structures that require certain strength, weldability and high corrosion resistance, such as the pipe, rod, sheet, and plate 6010 aluminum plate used in the manufacture of trucks, towers, buildings, ships, trams, furniture, machinery, etc.Sheet metal car.

2A16 Aerospace components with working temperature of 250~300 degrees Celsius, welding vessels and airtight cockpits working at room temperature and high temperature 2A14 Free forgings and die forgings with complex shapes 2A12 Aircraft skin bulkheads, ribs, spars, rivets, etc., construction and transportation Transportation vehicle structural parts 2A11 aircraft medium-strength structural parts Propeller blades Transportation vehicles and building structural parts.Medium-strength bolts and rivets for aircraft.

Disposal of the appearance of aluminum alloy produces waste water, which is mainly acid-base waste water, which contains a small amount of harmful anions and cations such as Ni2+Sn2+F-. The disposal method is acid-base neutralization.The wastewater is usually acidic, so it needs to be neutralized by adding alkali and adjust the PH value to about 75..At the same time during the neutralization process, the cations Al3+Ni2+Sn2+Cr3+, etc. all form hydroxide precipitates.The neutralized and precipitated waste water is pumped into the coagulation tank, and at the same time, the dissolved polyamide flocculant and waste are pumped with a quantitative pump.carbide rodsThe water coagulates, and the wastewater enters the sedimentation tank after coagulation. The sedimentation methods include inclined plate sedimentation, air floatation, centrifugal sedimentation, etc. The author believes that the conventional centrifugal sedimentation method is stable by comparison. Discharge pond or re-disposal penalty pond.Principles and methods of disposal and punishment of aluminum alloy appearance.

It is necessary to go out and conduct detailed investigations on the materials used in all walks of life to find materials suitable for replacement with aluminum alloys. Through these developments, the market for industrial aluminum alloy demand can be expanded, especially the development of large-scale industries, increasing market demand It can alleviate the fierce competition faced by the large and super large extrusion line under construction after completion.Improve the overall production technology of industrial aluminum alloy.Most industrial aluminum models have strict requirements on material performance, dimensional tolerances, etc..

Insufficient attention to downstream demand development, serious product homogeneity.In the past few years, the large-scale printing plate-based

Posted by: philiposbo at

07:38 AM

| No Comments

| Add Comment

Post contains 489 words, total size 4 kb.

vehicle owner should always look towards mending any mechanical or electrical issues when it occurs. Repairing the issue on time imparts durability and efficiency to the vehicle. One of the crucial factors that need to be checked on a regular basis is the brake pads and its surrounding areas. It is easy to detect refuelling of the vehicles as the meter will show you, but the brake pads need a manual check-up for best results. Changing Nissan Pathfinder brake pads will be cheap if you do it on time but ignoring it may cost you huge.

like the gas refuelling, there is no proper time as to when to change the parts and depends completely on the way you drive and the distance you have covered.

%A%A%A%A Hence, the entire diagnostics depend on the driver and the condition of the parts. Some of the obvious ways by which you can detect the weariness brake pads are given below.

Thinning of the packs

or the best detection manual check-up is always advisable. The shoes Tungsten Carbide Plates can be viewed without removing any parts. Through the wheels, the drum can be seen and you will even get to look at the condition of the shoes as well. These are seen cling to the rim of the wheel and if the width is not more than one third of an inch, you need to replace them immediately. Some of the newer models do have sensors attached to the pads to detect the thinning of them and you will get the notification on your dashboard with the blinking of a light.

Vibration in the pedals

If you get a sensation of vibration while applying the brakes there is a chance that the shoe needs to be replaced without wasting any time. In mechanical term, the vibration is known as pulsating. It can take place when the shoes have warped under high temperature. The issue can be resolved by carbide rods reshaping, but in case reshaping doesnt help, replacing it is obvious.

Different sounds emitted from the drum system

ven slight application of the brakes making sounds? There are different kinds of meaning to different sounds. If it is the clicking sound it is time to install new pads. A new car is installed with a device which restricts any regular noise from the car, but still, if you hear any sound on the application of brakes, you know you need to change the pads.

high pitched screening sound also directs toward wear and tear of brakes. In the case when the pads are fully worn or are displaced from its original position, screening sound is produced. When the sheet of metal comes in contact with the brakes, the screening sound is produced. It can inevitably be heard when the windows are rolled up and there is no music being played.

If you hear a growling sound it can be the brakes which are making it. This time it is not just the Nissan Pathfinder brake pads which need to be checked but the entire system including calliper and disc.

About the Author: This contribution has been made by Hamish Crotty who has written a number of articles on Nissan Pathfinder Brake Pads and provides fruitful information. To know more, please visit gtautoparts.com.au.

Posted by: philiposbo at

07:22 AM

| No Comments

| Add Comment

Post contains 563 words, total size 4 kb.

%ANow, the truck is used for different purpose across the world. Wide range of trucks is available with several models in the market. It is manufactured by people who specialist and talented in the sector. Manufacture offer numbers of products to clients such as bearings and spare parts. With the experience, manufacturers are providing quality of RENAULT RVI Truck Spare Part to buyers. They are offering the best range of products at a cheap rate. Specialist undergoes a specific procedure on making the spare parts.

%A%A%A%A Experts create these kinds of products with the latest technology to meet client need.

%A

%ASpare parts play an important carbide rods part in the automobile industry. It let people operate a truck without hassle. Suppliers are offering high-grade spare parts to your truck. All type of spare parts is avail with unique features that allows people to access the best one. Truck owners might find out spare parts that suit to your need. Different kinds of bearings and spare parts are created with unique and best design. However, manufacture provides bearings and spare parts at a lower cost. It provides a customized solution to the truck. It allows you to find spare parts based on dimensions and sizes. It let you choose the perfect one from the collection online.

¬hoose the right spare parts:

%AYou might access spare parts on the automotive units. It is designed by experienced manufacturers in the field. MACK Truck Spare Parts comes with exact design to equip on the truck without hurdle. You can search flawless and quality of products that suit to your vehicle. It offers an effective performance and used on all vehicle. These spare parts are available at a cheaper rate in the market. Manufacturers provide spare parts depend on the expectation of customers. It is accessed on industries like shipping, automobile, engineering, and others.

%A

%ASCANIA Truck Bearings come with superior quality that provides different options to people. Bearings are used by truck manufacturers to make the assembling of the vehicle on a certain procedure. It takes responsibility for the hard condition and helps people to utilize the best bearing. It is implemented on the assembling truck. It is offered by lots of suppliers online that provide options to invest on right bearings. It let you operate the truck in your convenient way. So, utilize exact spare parts and increase the life of the truck.

ªbout Author:

%APS Truck parts manufacturers all kinds of needle roller bearings, cylindrical roller bearings and rollers for MAN, MERCEDES-BENZ, Volvo, SCANIA, IVECO, RENAULT and DAF truck. Here we write about RENAULT RVI Truck Spare Part and SCANIA Truck Bearings. For more information about Truck Parts visit Pstruckparts.com

Posted by: philiposbo at

07:19 AM

| No Comments

| Add Comment

Post contains 458 words, total size 3 kb.

32 queries taking 0.0435 seconds, 96 records returned.

Powered by Minx 1.1.6c-pink.